Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

$45-85 /Square Meter

| Variety | |

| Contact Now |

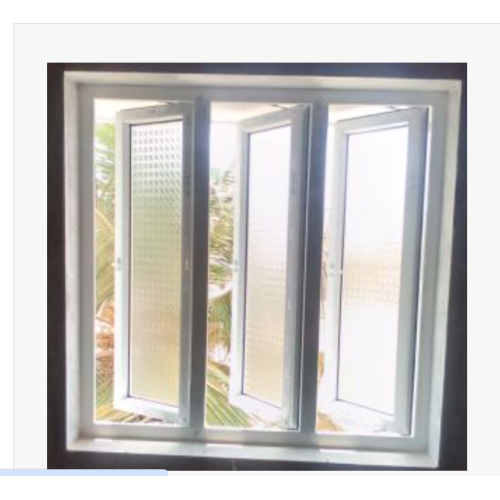

Model No.: WD-PCW0018

Brand: Wendou

Warranty Service: More Than 5 Years

After-sales Service: Free Spare Parts, Online Technical Support, Onsite Installation, Onsite Training, Onsite Inspection

Application Scenario: Hotel, Villa, Apartment, Office Building, School, Mall, Hospital, Workshop

Design Style: Contemporary, European, Asian, Modern, French, Chinese

Place Of Origin: China

Additional Functionality: Windproof, Anti-Theft, Dust-Proof, Heat Insulation, Insect Control, Invisible, Soundproof

Material: Pvc, PVC Profile+Tempered glass+Hardware

PVC Screen Netting Material: PVC/Stainless steel/Fiberglass

Main Material: PVC+Glass+Accessories

Glass: Tempered glazing+Laminated glazing+Low-E glazing+Reflective glazing+Frosted glazing

Color: Customized color based on your needs

Hardware: Germany brand/Chinese brand/American brand

| Selling Units: | Square Meter |

|---|---|

| Package Type: | Adhesive protective film+Bubber film+Hardboard+Strechable plastic wrap+Non-fumigation plywood-crate |

| Picture Example: |

Packaging: Adhesive protective film+Bubber film+Hardboard+Strechable plastic wrap+Non-fumigation plywood-crate

Productivity: 150000㎡/year

Transportation: Ocean

Place of Origin: Made in China

Supply Ability: 10000㎡/ per month

Certificate: NFRC/CE/AS2047

HS Code: 7610100000

Port: shenzhen

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

The file is encrypted. Please fill in the following information to continue accessing it

About Us

Related Products List

Contact Us

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.